Product of German MUNTERS EUROFORM GmbH

Purpose

In removing S02 from exhaust flue gases through flue gas desulphurization (FGD) it can be too easy to miss a golden opportunity to enhance profitability.

Instead of simply viewing FGD as a statutory requirement to reduce emissions of harmful substances, you can actually squeeze even more from your operations by installing efficient mist elimination systems and achieve tangible savings.

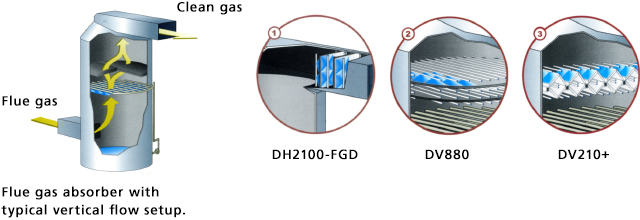

How mist elimination works in FGD

Exhaust flue gas is de-dusted and then it passes through the absorber where it is washed with a suspension of for example limestone in water or sea water. Acidic compounds in the exhaust gases react with this suspension. The S02 is absorbed into slurry droplets containing calcium sulphite that is then partly oxidized into gypsum. The cleaned gas passes through while the mist eliminator stops the liquid droplets from escaping into the atmosphere. Gypsum is a valuable byproduct of this process and it can be reclaimed and used, for example, by the construction industry.

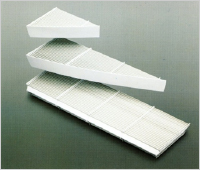

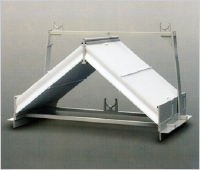

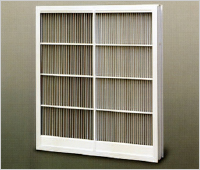

Type

Comparison of standard design

| Type | DV880 | DV210+ | DF2100-FGD | |||

| Design | Vertical - flat | Vertical - roof | Horizontal | |||

| Stages | [No.] | 2 | 3 | 2 | 3 | 2 |

| Velocity | [m/s] | 3.8** | 3.8** | 4.2** | 4.2** | 5*** |

| Rest content | [mg/Nm3] | <75* | <50* | <50* | <20* | <50* |

| Pressure loss*1 | [mbar] | 0.20-0.80 | 0.25-1.20 | 0.20-1.55 | 0.30-2.60 | 0.25-1.90 |

* Exact number upon submission of process design data

** Superficial gas velocity in absorber, data valid for flow variance of +/-25%

*** Superficial gas velocity inside the horizontal duct, data valid for flow variance of +/-25%

*1 Pressure loss data are based on gas density and are subject of reconfirmation+

Data given for min - max applicable velocities.