The type of Cent-Tarvon® Sheet Lining

- Cent-Tarvon®#1

- Cent-Tarvon®#10

- Cent-Tarvon®#10A

- Cent-Tarvon®#100

Application

(1)Light duty corrosion resistance : corrosion resistant layer only lining.

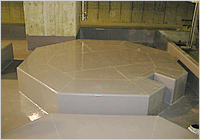

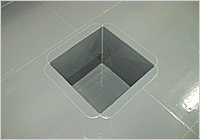

(2)Heavy duty corrosion resistance : For further protection of the lining, bricks and tiles are constructed on the lining layers.

Properties

Cent-Tarvon® sheets are semi rigid sheets, and their linings are adhesive linings. The joints of sheets are welded. Their welding requires high degree technique. CHUO BOSHOKU' s technique is excellent and skilled CHUO BOSHOKUcraftsmen can line constructions of any shape of the place in the field. When service temp is higher more than 65℃and the membranes may suffer physical abuse, bricks and tiles jointed with corrosion-resistant mortals are constructed to protect the membrane.

The characteristic of CENT TARVON®

| NAME(NUMBER) | Cent-Tarvon®#10 | Cent-Tarvon®#10A | Cent-Tarvon®#1,#100 | PVC |

| Material | Semi rigid vinyl chloride | The sheet laminated rigid vinyl chloride on the surface | Semi rigid vinyl chloride | Rigid vinyl chloride |

| Properties |

(1)Plasticity (2)Resistant to thermal expansion and shrinkage (3)Resistant to oxidizing acid, non-oxidizing acid, alkali salt and fat. |

(1)Plasticity (2)Resistant to thermal expansion and shrinkage (3)Resistant to oxidizing acid, non-oxidizing acid, alkali salt and fat. |

(1)Plasticity (2)Resistant to thermal expansion and shrinkage (3)Resistant to oxidizing acid, non-oxidizing acid, alkali salt and fat. |

(1)Excellent to hardness and rigidity. |

| apparent specific gravity | 1.3 - 1.35 | 1.3 - 1.35 | 1.35 | 1.4 - 1.5 |

| tensile strength ㎏/cm2 | 105 - 230 | 105 - 230 | 210 - 300 | 550 - 600 |

| flexural strength ㎏/cm2 | - | - | - | 980 - 1,050 |

| compressive strength ㎏/cm2 | 100 - 200 | 100 - 200 | 140 - 189 | 750 - 950 |

| thermal conductivity kcal/mh℃ | 0.12 | 0.12 | 0.11 - 0.18 | 0.13 |

| modulus of linear expansion (x10-5/℃) | 7 - 20 | 7 - 20 | 11 - 12 | 5.45 - 10.0 |

| elongation % | 200 - 300 | 200 - 300 | 250 - 400 | 50 - 150 |

| practical heat resistant temp℃ | 60 | 60 | 60 | 60 |